EDGE® Architectural Glazing Systems offers thermally broken window systems, complemented by double glazed and single glazed window systems. U-MAX®, MAX®, and GEN® aluminium window and door suites follow consistent design principles, the “EDGE DNA,” and deliver ease of manufacture, a true metric footprint, advanced drainage, and much more.

U-MAX thermally broken commercial window and door systems offers high energy efficiency ratings within a comprehensive range of commercial framing systems.

MAX, EDGE Architectural’s double glazed range, offers an array of interchangeable systems and door and sash elements to provide a complete, highly energy efficient range of products.

GEN is Australia’s next generation of single glazed architectural framing systems. In conjunction with U-MAX and MAX, GEN delivers complete compatibility.

The EDGE DNA

It’s not a window, it’s a system. A system with a DNA. The EDGE DNA instructs the development, form and functioning of all the EDGE Architectural framing systems.

By scoping U-MAX, MAX and GEN with the consistent features, our ranges can be interchangeably specified for visual unity and consistent, reliable, excellent performance. You chose the suite based on a desired U-value and maintain a consistent sightline around the building even when you alternate between frames.

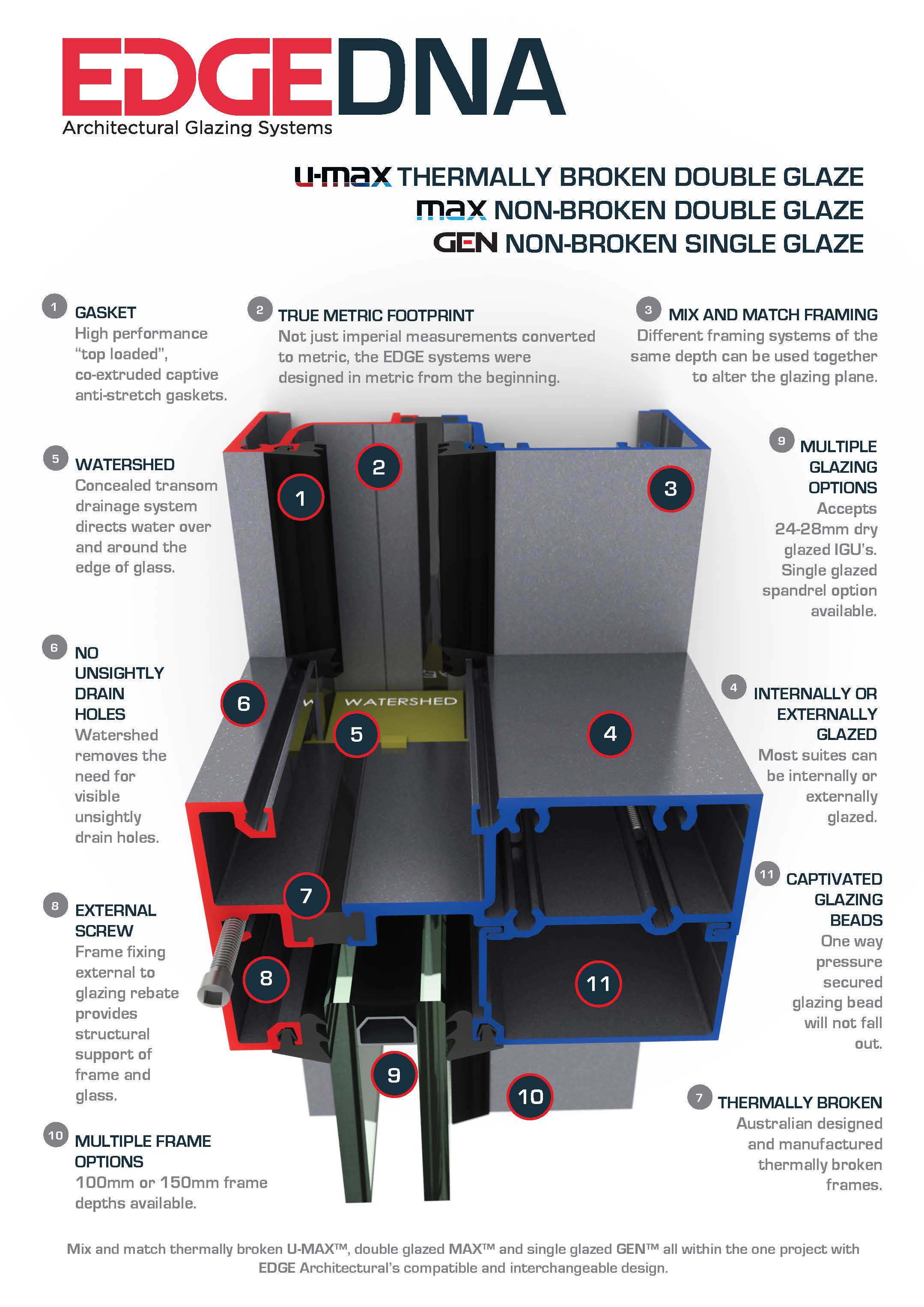

1. High performing gaskets

High performance, “top loaded”, co-extruded captive anti-stretch gaskets.

- Captive high-performance gasket

- Easily factory fitted

- Factory environment allows for greater quality control and cost savings

- Readily replaceable for reglazing or if damaged

- Consistent appearance finished result over silicone glazing

2. True metric footprint

Not just imperial measurements converted to metric, the EDGE systems were designed in metric from the beginning.

The Australian architectural window market largely remains the base commercial products introduced in the early 1960s, including the imperial dimensions. EDGE departs from the old standard. Incorporating frame and track systems, all EDGE products offer consistency in metrication.

3. Mix-and-match framing systems

Different framing systems of the same depth can be used together to alter the glazing plane.

Front, centre, and offset EDGE suites can be reversed and combined to change the glass plane. This gives designers freedom to introduce new elements and alter facades.

4. Internally or externally glazed

Most suites can be internally or externally glazed.

5. Watershed

Concealed transom drainage system directs water over and around the edge of the glass.

Once properly assembled, Watershed ensures water cannot run from the end of the transom on top of the glass or the glazing wedge. Watershed eliminates ugly external drain holes in the face of sills and transoms. Watershed allows the redirection of water in front of the glass, using vertical members (jamb and mullion) to direct water through the system for collection by the subsill.

6. No unwanted drain holes

Our Watershed system removes the need for drainage holes.

Beyond being ugly, drain holes in the face of a sill leaves the system vulnerable to other things. Air pressure, water, spiders and insects, all sorts of things can get in there. Where air goes, water will follow.

Our solution delivers a better drainage result and allows us to eliminate the drain holes. The EDGE suites are premium systems with premium drainage.

7. Thermally broken

Australian designed and manufactured thermally broken window and door frames.

Thermally broken window and door frames offer several advantages including energy efficiency, decreased condensation and reduced radiated cold, resulting in money saved and comfort increased. The EDGE team determined the best results could be attained for our clients by combining both Polyurethane and Polyamide strip technology in the U-MAX thermal break window and door frames.

8. External screw

Frame fixing external to the glazing rebate provides structure and support of the frame and glass.

The form and function of EDGE gets a boost from an external screw that increases strength and decreases the risk of transom torque and prevents the joint from opening and allowing water in.

9. Multiple glazing options

Accepts 24-28mm dry glazed IGU’s. Single glazed spandrel option available.

10. Multiple framing options

Variety of frame depths and glazing planes available.

- 100mm, 150mm, and 200mm frame depths available

- Centre glazed, offset glazed, front glazed, front capped, structural glazed, and curtain wall suites

11. Captivated glazing beads

One-way pressure secured glazing bead will not fall out when installed correctly.

Our glazing bead locks in place by locating into a captive groove under pressure from a glazing wedge or foam rod in the pocket. Glazing beads can be used on the underside of transoms, ensuring water is better contained within the glazing pocket.

The anti-drop out bead ensures the bead cannot dislodge. No other commercial aluminium window and door system offers this feature.

Performance Principles

The design principles behind EDGE Architectural’s systems emphasize offering more efficient ways to fabricate, install, and glaze products to increase design flexibility, quality control, cost control, and productivity.

Efficiency

EDGE Architectural combines the benefits of design freedom with high standards of energy efficiency in aluminium window and door framing systems.

U-MAX, our thermally broken suite, offers high energy ratings within a comprehensive range of architectural framing systems. Changing from double glazed to thermally broken gives approximately a 15 per cent improvement in the U-value.

Choice

Our integration across single glazed, double glazed and thermally broken frames is amazing. Our Pour & Debridge thermal break process allows us to offer the same product in broken or non-broken form.

Options include:

- Centre glazed

- Offset glazed

- Front glazed

- Front capped

- Structural glazed

- Curtain wall

- Operable sashes

- Apartment doors

- Top and bottom rolling tracks

- Commercial hinged, pivot, bi-fold, and sliding doors

Design Freedom

Break up facades, introduce new elements, create an impression, and do it all with EDGE.

Front, centre and offset glazed systems can be reversed and combined to change the glass plane. Interchange MAX, double glazed systems, and U-MAX, thermally broken systems, to maintain visual unity and achieve desired energy ratings around the structure. You’ll benefit from the beauty of their beauty and the freedom of their frames.

Quality

Our unwillingness to compromise ensures everything that leaves our factory meets our highest standards of quality control. Let us take away your worries. Our architectural frames will always be beautiful in form and reliable in function.

Aluminium Industries is an ISO 9001:2015 Quality certified company.

Strength

Aluminium window frame systems are strong, lightweight, and easy to maintain, making them an ideal choice for commercial construction since the 1960s. EDGE Architectural builds in from here.

Thermal break using Pour & Debridge (P&D) technology allows similar structural values as traditional unbroken systems (about 7 per cent of the original metal). This means strength can be maintained across the façade, alternating between broken and unbroken suites, without having to increase frame depth.

NOT A MEMBER?

JOIN THE  community

community

Access EDGE Technical Documents and CAD Files